INDUSTRIAL COMBUSTION BURNERS

Wymbs Inc is the exclusive distributor of Industrial Combustion burners for New York City (5 Boroughs), Westchester, Putnam, Dutchess, Nassau and Suffolk Counties, and Southern Connecticut. We carry an inventory of over 200 burners ready for immediate delivery.

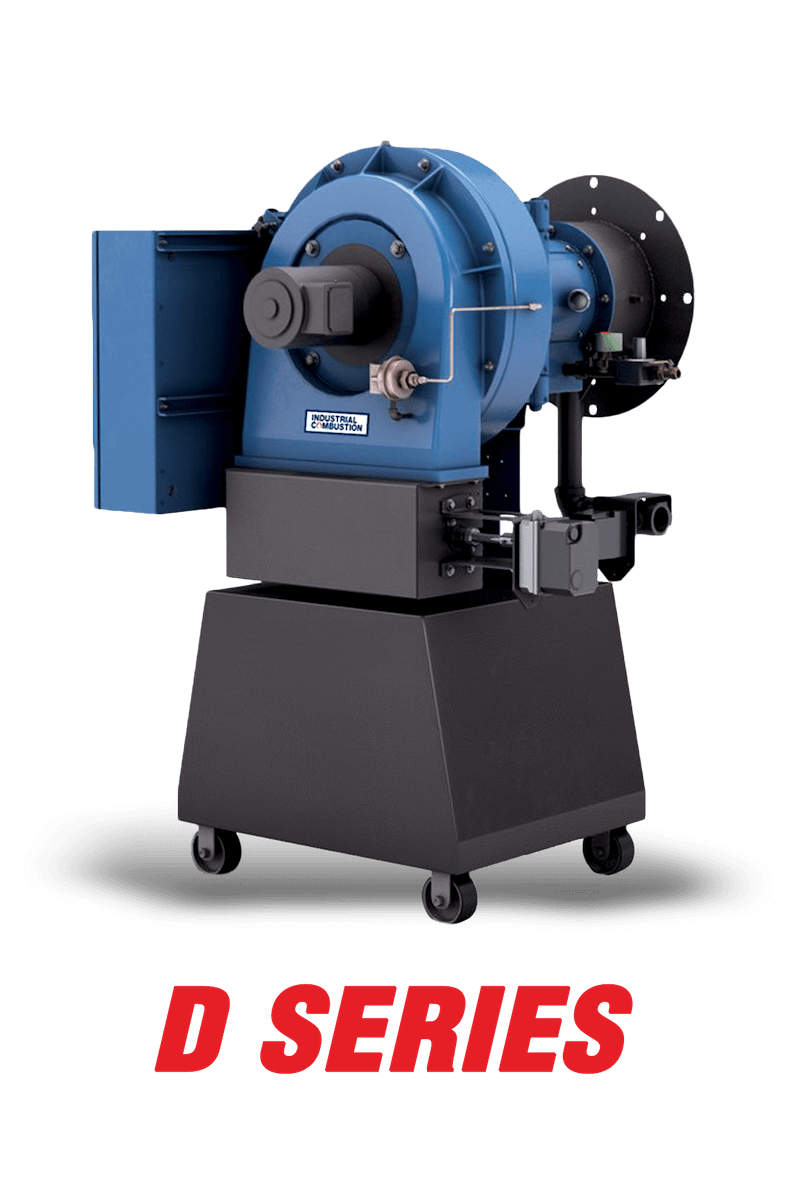

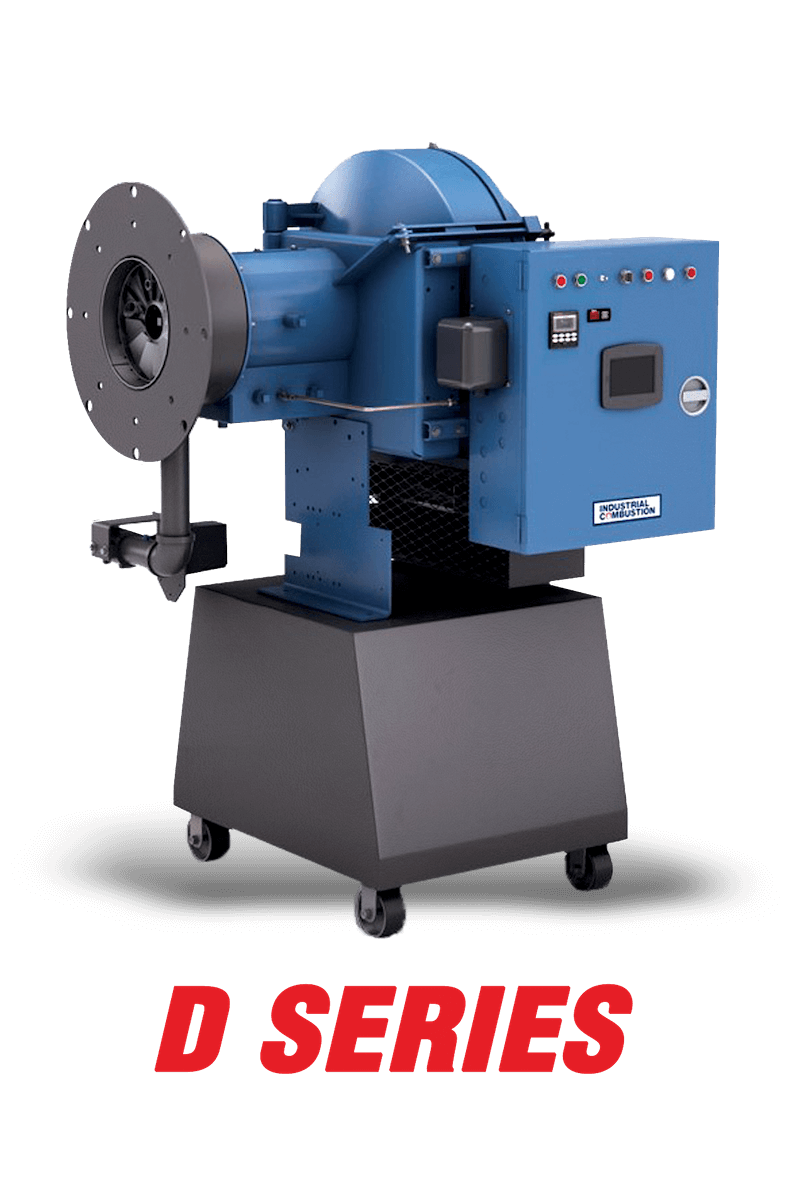

D/LND BURNER

D series burners are proven in boiler, heater, furnace, kiln and dryer applications.

The standard D series offers natural gas, propane gas, air atomized #2-#6 oil and combination gas/oil fuel options at capacities 4,200,000 to 42,000,000 MBTU/Hour.

The low NOx D series offers natural gas, propane gas, air atomized #2-#6 oil, and combination gas/oil fuel options at capacities from 3.4 to 42.0 MMBTU/Hour. Capable of delivering rated capacities against furnace pressures up to 4″ W.C.

Stock Burners Include:

DLG – Combination natural gas and air atomized #2 Oil

Low-pressure air atomizing system on oil with rotary vane compressor

Full Modulation

Auto Fuel Changeover

Piston-type positive displacement oil metering system

Hinged combustion head for easy access and maintenance

Backward-curved impeller provides combustion air for various furnace pressures

UL & cUL listed

Burners ranging in size from DLG 42 – 145 are in stock. Larger burners up to DLG 420 – 1000 HP Boiler must be special ordered.

Optional Features Include: (Special Order)

DG – Natural Gas only, DL – air atomized #2 Oil only, LNDL / LNDLG – Lo Nox D Burners, DMG – air atomized #4 oil and natural gas, DM – air atomized #4 oil, DEG – air atomized #6 oil and natural gas, DE – air atomized #6 oil

Siemens ventless gas trains (Fully assembled) in stock and available for delivery

Parallel positioning available for optimal control throughout the firing range (Siemens LMV, Fireye Nexus & PPC, Honeywell Control Links)

High Efficiency (TEFC) Motors

VFD Drives for high efficiency motors (Requires Parallel Positioning)

Cam trim available with 14-point adjustment range for consistent air/fuel ratios

Low NOx with FGR capabilities

FGR modulating valve

Nozzle line electric heater standard on medium to heavy oil burners

Many other accessory items including Sequence Draft Control System, Lead Lag System, and Smoke Opacity Monitors

Burners can be built to job specifications

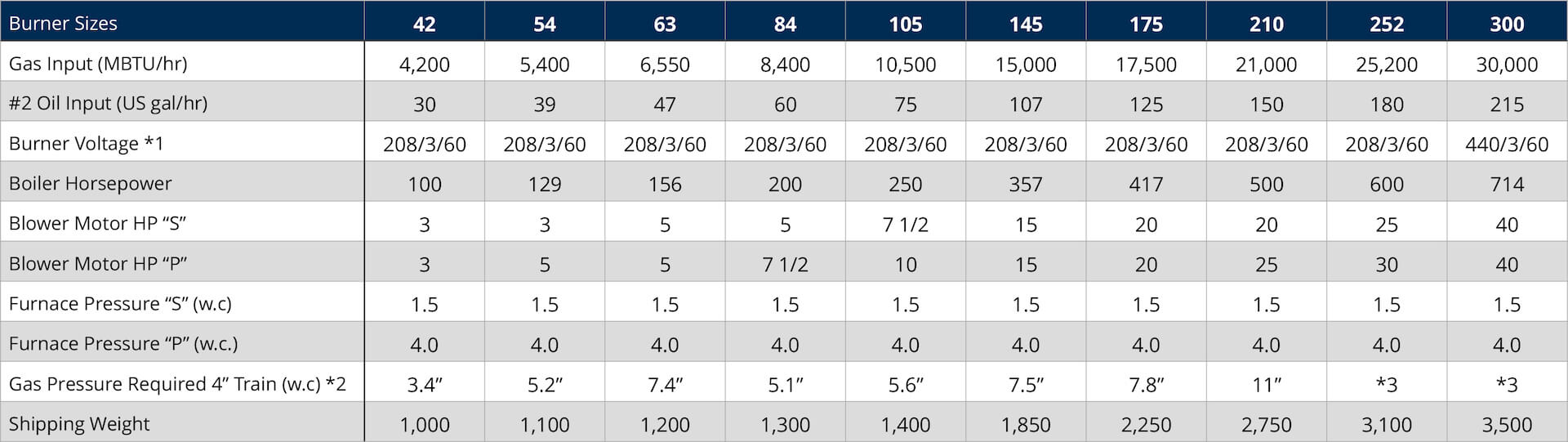

Capacities and Specifications (Stock DLG Burners)

*2 Minimum gas pressure required at train inlet with a 4″ Siemens Gas Train, please call for pressure requirements on smaller Siemens Gas Trains. A gas booster is required for lower pressures than listed, we can supply you with an Eclipse Gas Booster.

*3 Please call us for gas pressure requirements on DLG 252 and larger.

M BURNER

M series burners are designed for boilers, heaters, furnaces, kilns and dryers.

The M series offers natural gas, propane gas, air atomized #2-#6 oil and combination gas/oil fuel options at capacities from 1,400,000 to 10,500,000 MBTU/Hour. Full modulation and cam trim adjustment provides optimum performance for load demand.

Stock Burners Include:

MMG #2 Oil – Combination natural gas and air atomized #2 Oil

Low-pressure air atomizing system on oil with rotary vane compressor

Full Modulation

Auto Fuel Changeover

Piston-type positive displacement oil metering system

Hinged combustion head for easy access and maintenance

Backward-curved impeller provides adequate combustion air for furnace pressures

UL & cUL listed

Burners ranging in size from MMG 22 – 84 are in stock ready for immediate delivery. MMG 14 & 105 must be special ordered.

Optional Features Include: (Special Order)

MG – Natural Gas only, MM – air atomized #2 Oil only, MM – air atomized #4 Oil, MMG – air atomized #4 oil and natural gas, ME – air atomized #6 oil. MEG – air atomized #6 oil and natural gas

Siemens ventless gas trains (Fully assembled) in stock and available for delivery

Parallel positioning available for optimal control throughout the firing range (Siemens LMV, Fireye Nexus & PPC, Honeywell Control Links)

Cam trim available with 14-point adjustment range for consistent air/fuel ratios

Low NOx with FGR capabilities

FGR modulating valve

Nozzle line electric heater standard on medium to heavy oil burners

Many other accessory items including Sequence Draft Control System, Lead Lag System, and Smoke Opacity Monitors

Burners can be built to job specifications

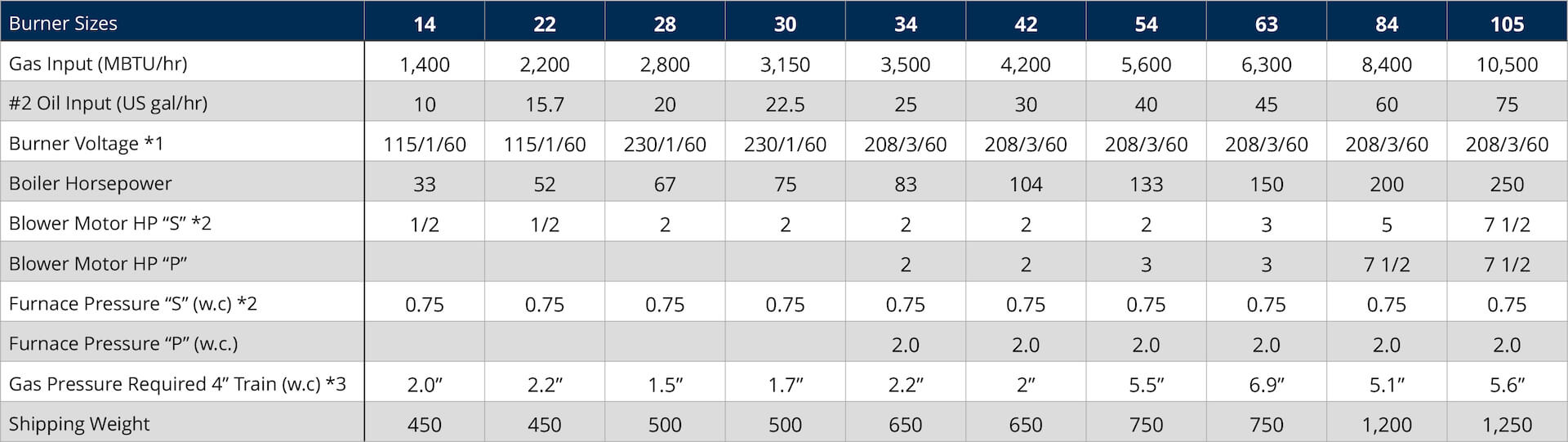

Capacities and Specifications (Stock MMG Burners)

*2 MMG 14-30 do not have an “S” or “P” designation

*3 Minimum gas pressure required at train inlet with a 4″ Siemens Gas Train, please call for pressure requirements on smaller Siemens Gas Trains. A gas booster is required for lower pressures than listed, we can supply you with an Eclipse Gas Booster.

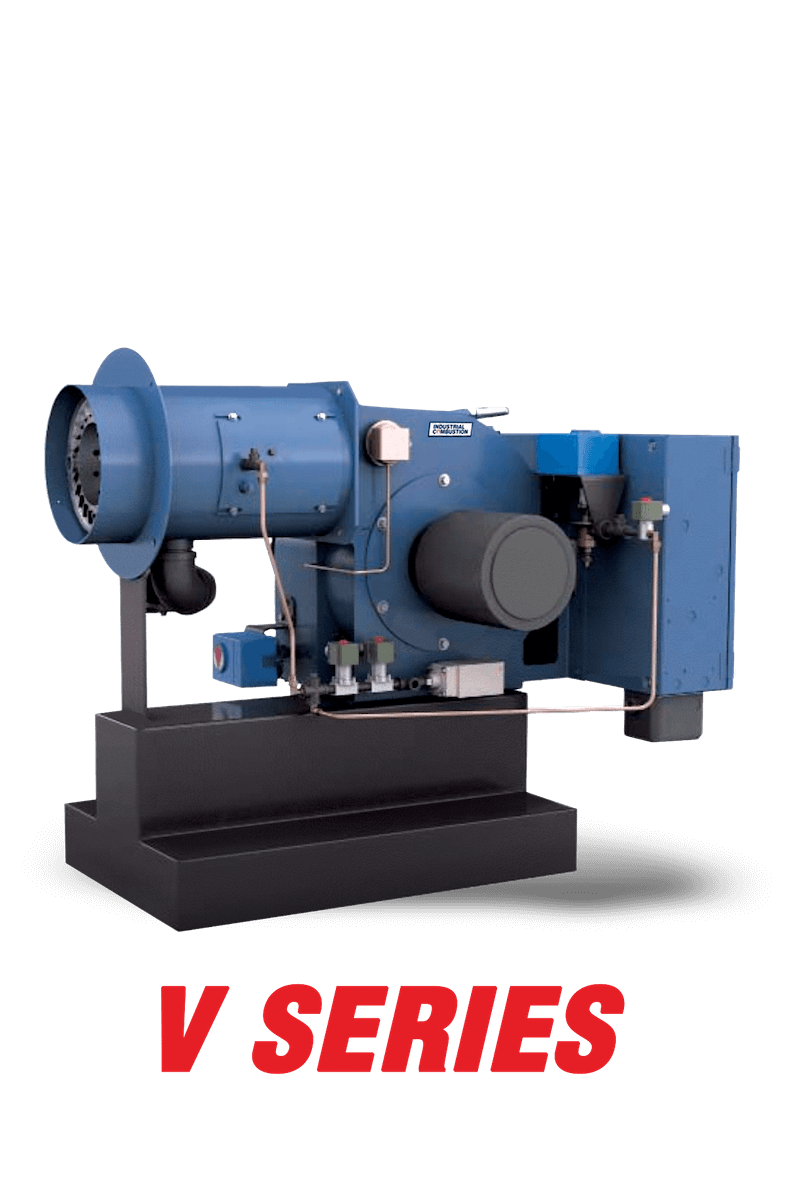

V/LNV BURNER

V series burners are suitable for firetube, watertube and cast iron boilers.

V series features a unique aerodynamic air damper design which permits accurate air-to-fuel settings for maximum combustion efficiency. The standard V series offers natural gas, propane gas, pressure atomized #2 oil and combination gas/oil fuel options at capacities from 1,300,000 to 16,800,000 Btu/hour.

The low NOx V series offers natural gas, propane gas, pressure atomized #2 oil, and combination gas/oil fuel options at capacities from 1,300,000 to 14,700,000 Btu/hour. Through the use of advanced technology, the V series offers high turndown up to 10:1 on natural gas (requires parallel positioning to obtain 10:1 turndown), and low emission capabilities with turndown up to 5:1.

Stock Burners Include:

VLG – Combination natural gas and pressure atomized #2 Oil

For Firetube Boilers (Special Order for Cast Iron & Watertube Boilers)

Fireye Flame Safeguard (Less Display Module)

Full Modulation

Auto Fuel Changeover

Remote Oil Pump

Unique aerodynamic air damper design for optimal flow control

Forced draft for clean and efficient combustion

UL & cUL listed

Siemens Ventless Gas Train (Loose Components – Must be assembled by Contractor – Fully assembled trains can be supplied for an additional charge)

Wymbs has a full inventory of stock VLG burners ranging in size from VLG-13 to VLG 84 ready for delivery. V Burners with optional features can be special ordered from our factory with a normal lead time of 4-6 weeks, please call us for additional information.

Optional Features Include: (Special Order)

VG – Natural gas only, VL -pressure atomized #2 oil only, and LNV – Lo Nox V burners

Display Module for Flame Safeguard

Honeywell Flame Safeguard

Cam trim with 14-point adjustment range for consistent air/fuel ratios

Parallel positioning available for optimal control throughout the firing range (Siemens LMV, Fireye Nexus, Honeywell Links)

Up to 10:1 turndown on natural gas (requires parallel positioning to achieve 10:1 turndown) and optional low NOx with up to 5:1 turndown

Top or rear mount panel options

Induced FGR

FGR modulating valve

FGR shutoff valve

Cam trim available with 14-point adjustment range on FGR

Many other accessory items including Sequence Draft Control System, Lead Lag System, and Smoke Opacity Monitors

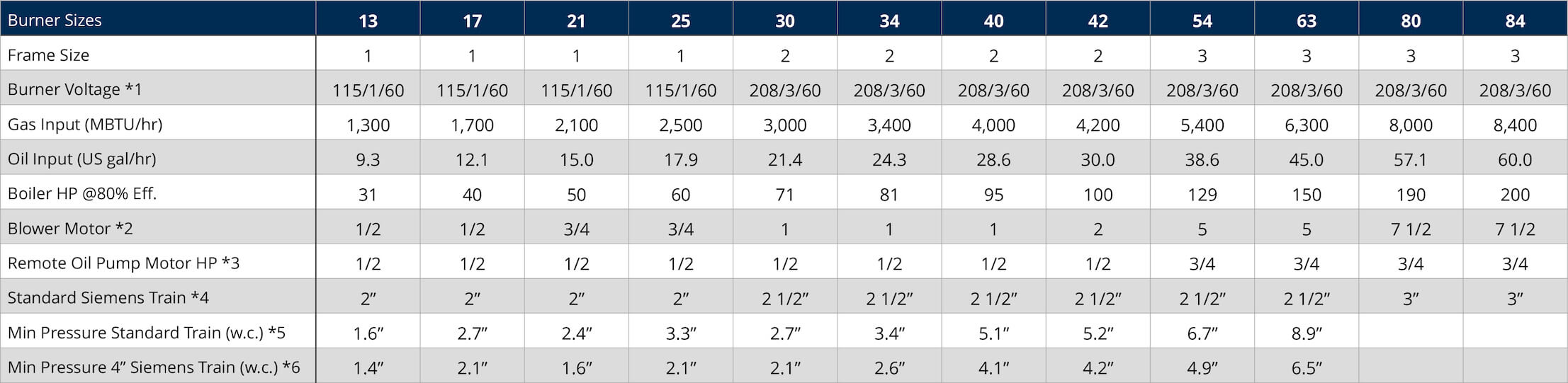

Capacities and Specifications (Stock VLG Burners)

*2 Motor ratings for gas only or gas/oil burners using a remote oil pump

*3 Remote oil pump standard on our stock burners

*4 Standard Gas Train size on our stock burners – train can be upgraded to larger gas train

*5 Minimum pressure required at train inlet for standard gas train – please call for minimum pressure for other gas train sizes

*6 Minimum gas pressure required at train inlet with a 4″ Siemens Gas Train, A gas booster is required for lower pressures than listed above, we can supply you with an Eclipse Gas Booster.

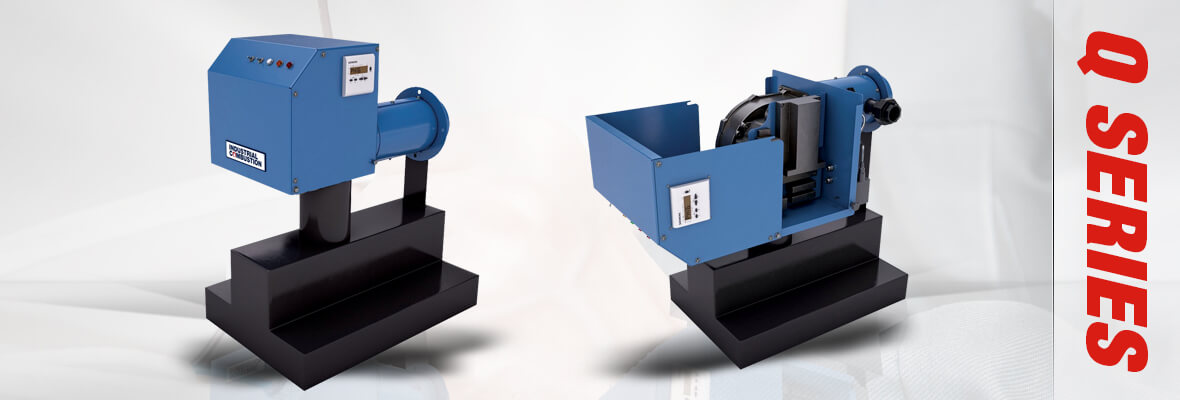

Q BURNER

Q Series burners are designed around efficiency and operational simplicity.

The Q series is perfect for cast iron sectional boilers, firebox, commercial watertube, firetube, furnace and oven applications.

The standard Q series features linkageless operation with DC pulse width modulation and parallel positioning gas actuator control for increased efficiencies and ease of use.

Stock Burners Include:

Linkageless System standard for optimal control throughout the firing range

DC Pulse Width Modulation allows full blower speed control without the use of air dampers

Fully enclosed air housing features a hinged cover for easy access to internal components and quiet operation

Combustion air fan efficient airfoil blade design smoothly lifts airflow over the entire blade, resulting in less motor horsepower requirements and significant noise reduction when compared to standard force draft fans

Sealed combustion eliminates the need for outside air dampers and make-up air units typically required in every boiler room.

UL & cUL listed

CSA package listed

The standard Q series includes on/off or full modulation linkageless operation and offers natural gas from 0.375 to 2.5 MM BTU per hour. Its totally enclosed, compact design allows provisions for sealed combustion or fresh air intake. Outside air can easily be connected to the blower inlet without any modifications to the burner.

Additional Features Include:

- On-off, low-high-low, or full modulation utilizing a parallel positioning gas flow ratio control

- Parallel positioning gas actuator control with pulse width modulation makes setup as easy

Linkageless system utilizes a DC pulse width modulation blower and gas actuator control to simplify burner setup and operation

- DC pulse width modulation reduces electrical and maintenance costs and produces a quiet operation

Gas actuator controls the fuel and proportions the gas to a predetermined flow

- Fully enclosed air housing features a hinged cover for easy access and a whisper quiet operation

Increased combustion air fan efficiency requiring lower blower motor horsepower, thus increasing electrical savings.

Our friendly, knowledgeable staff can assist you in choosing the correct burner model and size for your application. We can also help with troubleshooting on the job, as well as providing the correct replacement parts to repair Industrial Combustion Burners.

SBR-30 BURNER

Low-NOx burner with lowest emissions and highest efficiency.

CONTACT US

Our factory trained technicians are ready to help over the phone or meet you on the job.

PHONE

718-295-3500

joe@wymbs.com

BUSINESS HOURS